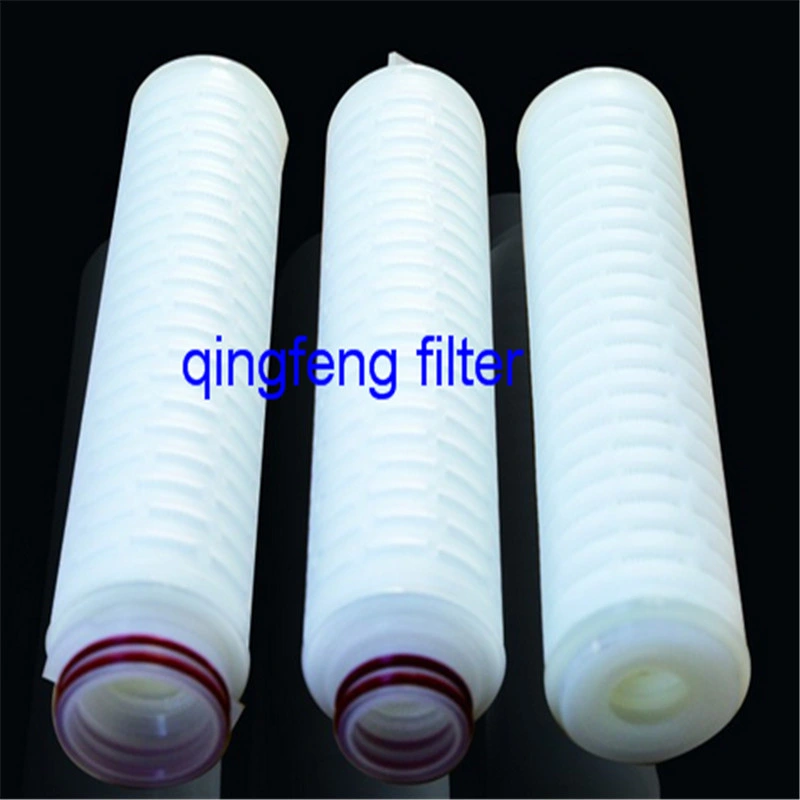

PES Filter Cartridge

Introduction:

The filtration media of PES micropore filter cartridge is PES membrane. High porosity(about ≥80%) and geometrically unique pores of the PES cartridge contribute to high throughputs for difficult-to-filter solutions. It is constructed of two materials PES and PP to meet high standards of chemical and pharmaceutical industry. The benefit summary: unique hydrophily, no including surfactant and lubricant, so it provides wide filtration pore size and high folow rate, its wide range of PH values and lower adsorbance of protein and valuable biologicals, high retention rate, super chemical tolerance and thermal stability, good intension, withstand shocks and back pressures. All products have passed 100% integrity testing.

Specification:

Filter medium: hydrophily PES membrane

Support layer: PP

Filter cage: PP

Pore size: 0.1, 0.2, 0.45, 0.65, 1 (um)

Length: 5", 10", 20", 30", 40"

Sealing material: Silastic, NBR, EPDM, Viton

Airtight method: thermal bonding technique

Effective filtration area: ≥0.57square meter/10inch

Diameter: 68mm

Working temperature: ≤60ºC

Max. operating temperature:90ºC, 0.01Mpa

Max. bear temperature: 140ºC, 0.28Mpa

Max. positive pressure: 0.42Mpa (23ºC)

PH value: 2--13

Sterilizing temperature: 121ºC 30min

Others: special requirement of diameter and end caps can be customized

Seloct filter cartridge, refer to P10 (Interface/End caps)

Typical Applications:

Pharmacy industry; Food industry; Electronic industry etc.

Introduction:

The filtration media of PES micropore filter cartridge is PES membrane. High porosity(about ≥80%) and geometrically unique pores of the PES cartridge contribute to high throughputs for difficult-to-filter solutions. It is constructed of two materials PES and PP to meet high standards of chemical and pharmaceutical industry. The benefit summary: unique hydrophily, no including surfactant and lubricant, so it provides wide filtration pore size and high folow rate, its wide range of PH values and lower adsorbance of protein and valuable biologicals, high retention rate, super chemical tolerance and thermal stability, good intension, withstand shocks and back pressures. All products have passed 100% integrity testing.

Specification:

Filter medium: hydrophily PES membrane

Support layer: PP

Filter cage: PP

Pore size: 0.1, 0.2, 0.45, 0.65, 1 (um)

Length: 5", 10", 20", 30", 40"

Sealing material: Silastic, NBR, EPDM, Viton

Airtight method: thermal bonding technique

Effective filtration area: ≥0.57square meter/10inch

Diameter: 68mm

Working temperature: ≤60ºC

Max. operating temperature:90ºC, 0.01Mpa

Max. bear temperature: 140ºC, 0.28Mpa

Max. positive pressure: 0.42Mpa (23ºC)

PH value: 2--13

Sterilizing temperature: 121ºC 30min

Others: special requirement of diameter and end caps can be customized

Seloct filter cartridge, refer to P10 (Interface/End caps)

Typical Applications:

Pharmacy industry; Food industry; Electronic industry etc.

| Materials of Construction | |

| Filter Media | Highly Asymmetric, Hydrophilic PES |

| Core, Cage | PP |

| End Caps | PP |

| O-rings/Gasket | Silicone/EPDM/Viton |

| Sealing technology | Thermal Bonding, No Adhesives |

| Dimensions | |

| Diameter | Φ 68 (2.67 in) |

| Length(in) | 5, 10, 20, 30, 40 |

| Filtration Area | |

| ≥ 5.7 ft2/10 in (≥ 0.53 m2/250 mm) | |

| Pore Size, μm | |

| 0.1, 0.22, 0.45, 0.65,1.0 | |

| Maximum Forward Differential Pressure | |

| 4.2 bar@23ºC | |

| Integrity Test- water bubble point at 23 ºC | |

| 0.22μm:≥3100mbar (44.96psi) | |

| 0.45μm:≥1800mbar (26.1psi) | |

| Sanitization | |

| May be hot water sanitized for 30 cycles using purified water at 85ºC(185ºF) for 30 minutes. | |